- +8618937185591

- +8618937185591

- ec19@zkcorp.com

- +8618937185591

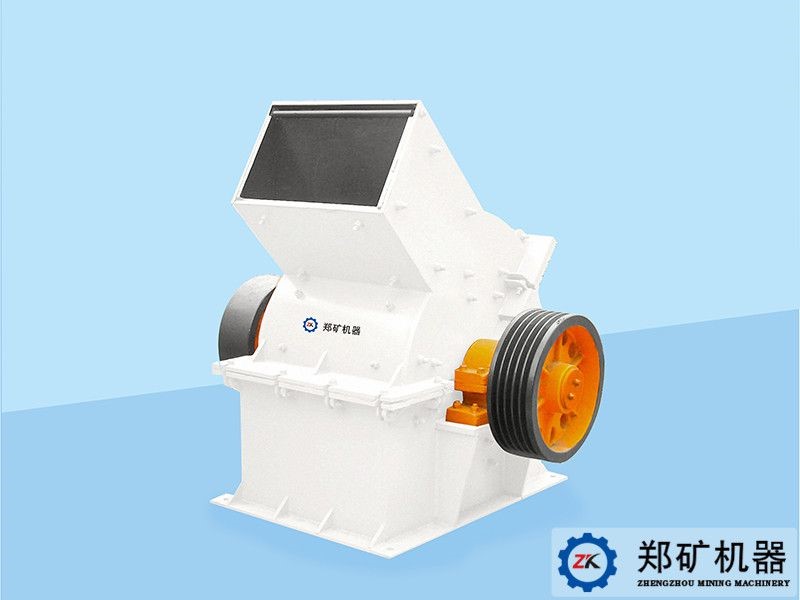

I. Equipment Introduction

The Hebi hammer crusher project is mainly equipped with pc800×600 hammer crusher with a capacity of 20-50 t/h. The product has the characteristics of small volume, light weight, simple structure, easy operation and maintenance, large crushing ratio, small Over-crushing, uniform product granularity, high production capacity, etc. It is suitable for crushing various materials with brittleness, medium hardness and 150MPa compressive strength.

II. Working principle

Hammer Crusher mainly relies on impact to complete the work of crushing materials. When the hammer crusher works, the motor drives the rotor to rotate at a high speed, and the material enters into the crusher cavity evenly. The high-speed rotating hammer head impacts and cuts the material and causes the material to be broken. At the same time, the gravity of the material itself makes the material rush from the high-speed rotating hammer head to the baffle plate and sieve bar in the frame, and the material larger than the size of the sieve hole stays on the sieve plate and, until it is crushed to the required discharge granularity and discharged out of the machine through the sieve plate.

Ⅲ. Equipment advantages

1. Hammer head and other vulnerable parts are made of excellent materials, which greatly prolongs the service life;

2. The product has controllable particle size, good particle shape, simple structure and convenient maintenance and operation;

3. Smash the structure seal of the machine body to solve the dust pollution and dust leakage problems in the crushing workshop;

4. Large feeding port and high crushing cavity are suitable for high hardness and block size of materials, less stone powder and less crushing power consumption.