- +8618937185591

- +8618937185591

- ec19@zkcorp.com

- +8618937185591

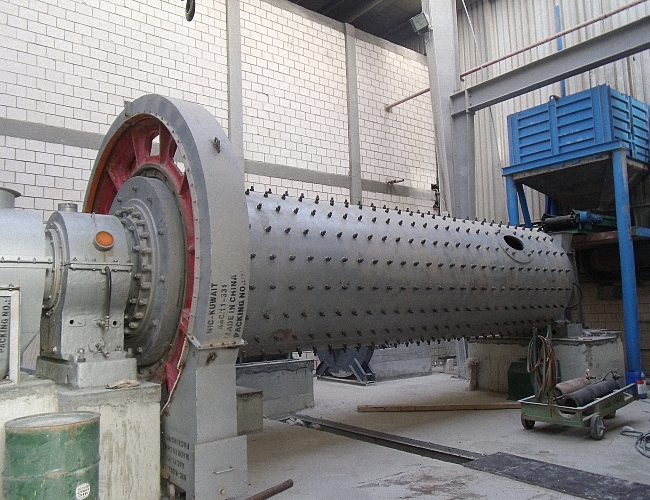

Since the advent of the roller ball mill,it has been widely used in the crushing of raw materials in a number of basic industries such as mining, metallurgy, building materials, chemicals and power sectors.

Since the advent of the roller ball mill,it has been widely used in the crushing of raw materials in a number of basicindustries such as mining, metallurgy, building materials, chemicals and power sectors.

With the increasingly fierce marketcompetition, how to save energy and reduce production costs are the concerns ofthe Zheng mining machine, therefore, to minimize the power consumption andenergy conservation of the drum-type ball mill is of great significance toimprove the economic efficiency of enterprises.

1. The existing ball mill start-up mode andcontrol mode is not saving, can save a lot of electricity through frequencyconversion.

2. The existing start-type ball millstarted by the impact of the very large, so the roller ball mill bearings andreducer gear easily damaged, large maintenance costs.

3. The drum-type ball mill start with theexisting start-type ball mill impact current is large (usually rated current of7 to 8 times), will cause the grid voltage fluctuations, voltage drop, in seriouscases will cause other equipment tripping and Failure, affecting normalproduction.