- +8618937185591

- +8618937185591

- ec19@zkcorp.com

- +8618937185591

In addition to linear vibrating screens, what are other mining screening equipment?

When it comes to mining screeningequipment, we first think of linear screens because of its wide application.Linear screens are favored by many concentrators because of their high screeningaccuracy and low energy consumption. So, do you know which mining screeningequipment besides the linear screen? What are their advantages? How to choosewhen selecting?

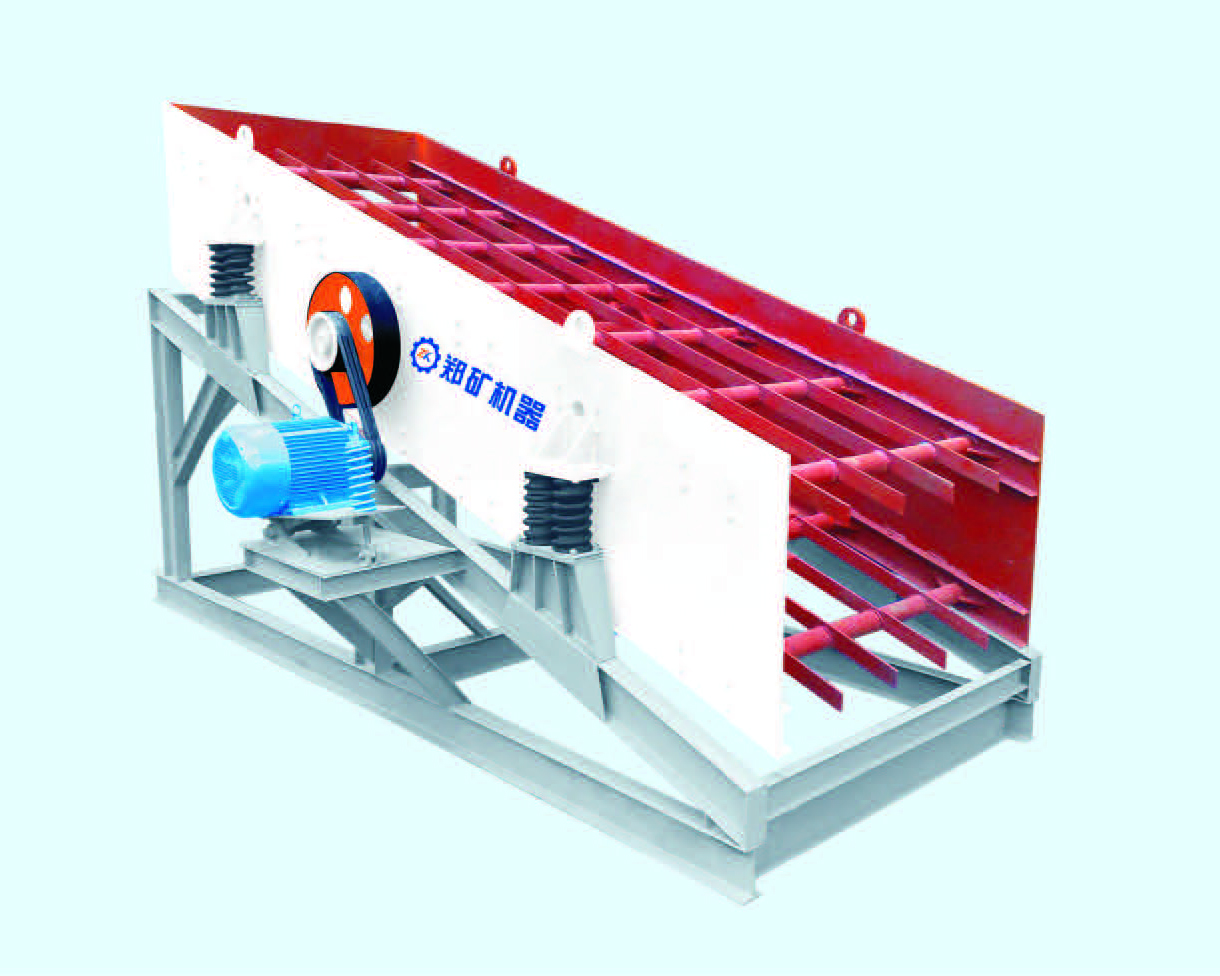

1. Linear vibrating screen

ZK series linear vibrating screen is basedon the production needs of China, on the basis of digesting and absorbingforeign vibrating screens, summing up our years of research design and useexperience, combined with China's national conditions to develop a new seriesof vibrating screens.

Feeding particle size: <250mm;

Processing capacity: 4.5-756 (t / h);

Applicable materials: coal, metallurgy,mining, power generation, building materials industry, water conservancyengineering, light industry and chemical industry;

Through years of production practice, itproves that this series of sieve machines has the advantages of largeprocessing capacity, reasonable technical parameters, high structural strength,high rigidity, serialization, generalization, high degree of standardization,stable and reliable operation, low noise, and convenient maintenance.

2. YA series circular vibrating screen

YA series circular vibrating screen ismainly used in coal, metallurgy, mining, power generation, building materialsindustry, water conservancy engineering, light industry and chemical industry.A high-efficiency screening equipment for classifying bulk materials such ascoal, ore, and coke.

Processing capacity: 50-500 (t / h);

The movement of the vibrating screen isdriven by a motor through a triangular tape to drive a vibrator having aneccentric mass, and the screen box is vibrated, and the movement path of thescreen box is circular. The vibrating screen is composed of a screen box, avibrator, a spring damping device and a supporting chassis. The screen box is connectedby advanced ring groove rivets to form a frame structure. The vibrator uses aneccentric shaft and an eccentric block. The spring damping device uses a steelcoil spring.

3. YK series circular vibrating screen

YK series circular vibrating screen introduceshigh-efficiency vibrating screen made by German technology. It is suitable forquarrying sand and gravel materials, and can also be used in coal preparation,mineral processing, building materials, electric power and chemical industries.

Processing capacity: 20-900 (t / h);

Applicable materials: Suitable for coal,metallurgy, mining, power generation, building materials industry, waterconservancy engineering, light industry and chemical industry;

Features and advantages: 1. Using blockeccentricity as excitation force, strong excitation force; 2. Screen beam andscreen box are connected by high-strength bolts, no welding; 3, sieve machineis simple in structure, convenient and quick to repair; 4, using tire Coupling,flexible connection, stable operation; 5, high screening efficiency, largeprocessing capacity and long life.

4. GS rotary drum sieve

GS rotary drum screen is a kind of beneficiationequipment which is classified according to the particle size of materials. Itis generally used for grading and screening of medium and fine grain materials.It has the characteristics of stable operation, low energy consumption, easymaintenance and simple and flexible process layout. It is widely used in theclassification of products in mining, building materials, transportation,energy, chemical and other industries, especially for the grading and screeningof ceramsite.

Processing capacity: 1 (t / h) - 70 (t /h);

Applicable materials: ceramsite, mining,building materials, transportation, energy, chemical and other industries.

After the broken stone enters the drum, onthe one hand, it is screened as the drum rotates. On the one hand, thecoarse-grained stone flows forward along the slope of the drum, and isgradually screened out through the screen of different meshes. Small stones aresieved out and dropped into their respective funnels, which are then manuallytransported or fed to the finished product pile.