- +8618937185591

- +8618937185591

- ec19@zkcorp.com

- +8618937185591

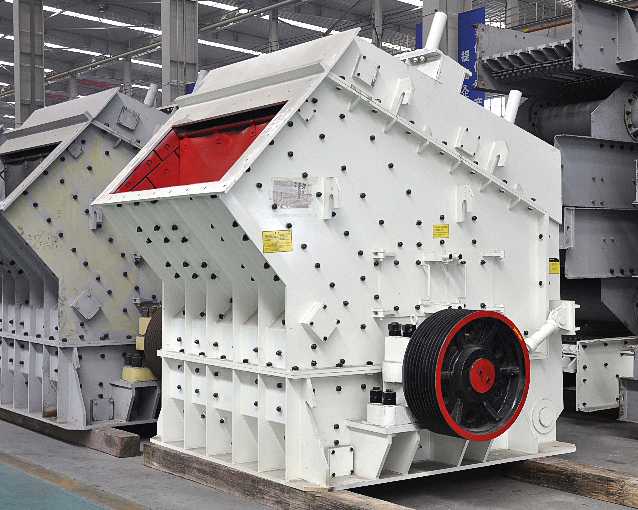

In the process of making sand, the impact crusher often causes the loss of wear parts of the impact crusher very quickly due to the factors of the working environment or improper operation, which increases the production cost.

In the process of making sand, the impact crusher often causes the loss of wear parts of the impact crusher very quickly due to the factors of the working environment or improper operation, whichincreases the production cost. Therefore, the use of equipment shouldstrengthen the maintenance work before the equipment can be used well and workefficiently. Let's take a look at the maintenance of the impact crusher.

1. To deal with the impact crusher bearingmaintenance. First of all, the bearing temperature rise should not exceed 35°C, the maximum temperature rise does not exceed 70 °C. Second, the replacementof lubricating oil, should pay attention to cleaning, no impurities can enter.

2. The hammerhead part is a key part of theequipment and it should be specially strengthened to protect and maintain it.Because the hammerhead is the most easily worn part of the impact crusher, thehammerhead should be frequently torn down and turned over on time. This willnot only make the hammerhead wear evenly, but also make the rotor run inbalance and increase the service life of the hammerhead. These are the mostdirect ways to maintain the hammer.

3. Due to more dust on the production site,although regular maintenance is performed, abnormal wear often occurs, whichseriously affects the productivity of crusher equipment. Therefore, it isrecommended that the ZK CORP add a seal ring and oil seal at the sealing partof the main shaft. It is also possible to use a ladder structure and combinethe size to enhance its sealing performance.

4. Usually deal with the equipment to conducta comprehensive inspection, if any problems should be resolved in a timely manner,can not work with faults or problems.

5. Should always take care of dust, so as toavoid the machine encountered the material can not be broken, the mobilebearing can not move on the chassis, leading to serious accidents.

6. The new installation of the tire is proneto loosening, must be checked regularly. In particular, if the impact of therotating gear in operation, should immediately stop and check.

The above is related to the maintenance ofthe impact crusher by the ZK CORP. The friends in need welcome onlineconsultation to learn more about the impact crusher.