- +8618937185591

- +8618937185591

- ec19@zkcorp.com

- +8618937185591

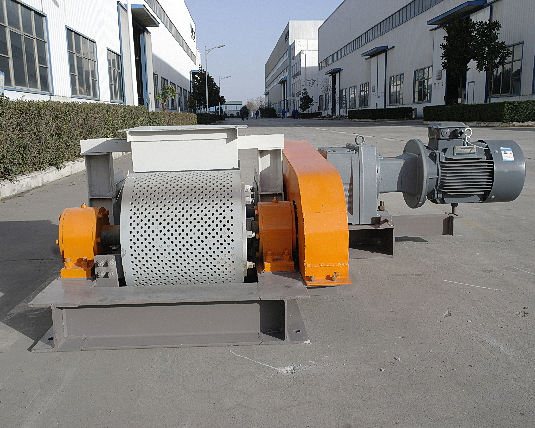

The ceramic sand granulator is mainly composed of a disc, a shaft seat, a speed reducer, a motor, a frame, a tug wheel group and the like.

First, the structure of ceramic sand granulator

The ceramic sand granulator is mainly composed of a disc, a shaft seat, a speed reducer, a motor, a frame, a tug wheel group and the like.

1. Disc: It is made of several kinds of steelplates with different thicknesses. It has certain strength and rigidity and isthe main component of the ball.

2. Shaft seat: Connecting disc and reducer.

3. Reducer: ZDY280 reducer (outsourced), sothat the ball reached the required speed.

4. Motor: Each disc pelletizer is equippedwith a Y280S-4 motor.

5. Rack: composed of channel steel,supporting the disk surface, the installation must maintain the ground level.

Second, ceramic sand granulator installationand commissioning

After the new machine is installed, it shouldbe checked as follows:

1. Check the insulation resistance of themotor windings to the ground. If it is damp during transportation, it must bedried before it can be used.

2. Check the wiring of the motor.

3. Check the machine, motor connection screwsmust be tightened.

4. Check the rack, the installation isstable, not allowed to hang.

5. Check the various parts of the oil device,lubricating oil to be added.

6. No problem with the above, before they canstart the trial run, first no-load for half an hour, here to observe whetherthe machine starts smoothly, whether the operation is balanced, no specialbuzz. Everything is normal before it goes into production. Note: This machinestarts requiring variable frequency start.