- +8618937185591

- +8618937185591

- ec19@zkcorp.com

- +8618937185591

Fly ash ball mill is a grinding device for finer output size of fly ash.

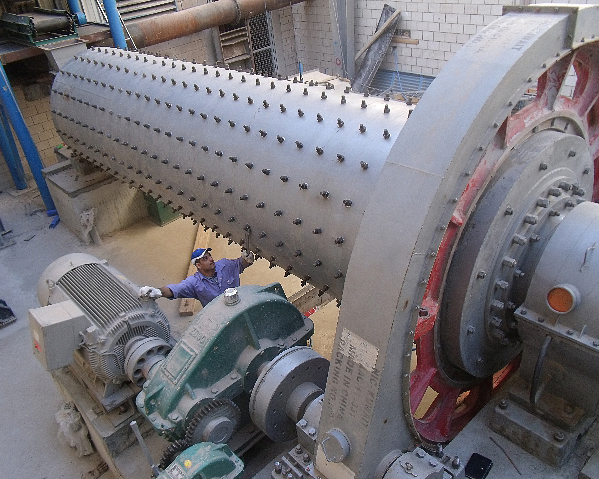

Fly ash ball mill is a grinding device for finer output size of fly ash. The equipment is stable in operation, reasonablein structure, strong in carrying capacity, and has a large unit handlingcapacity. The fine powder is uniform and the grain size can be within a certainrange. To adjust, in order to facilitate users to understand a full range ofspecial fly ash ball mills, the following ZK CORP describes its workflow,structure, components and so on.

Fly ash ball mill workflow

The material is sent to the feed port of aspecial ball mill for grinding and enters the ball mill for grinding. Thematerial after grinding by the special ball mill contains a large amount offine ash, and is fed into the separator by the elevator again. The fine ash issorted out. Subsequent conveying equipment is sent to the finished ash store.The dust collection system is provided at the tail of the grinding mill fordust collection. Compared with the open circuit (without powder separator)system, this closed-circuit grinding process can increase the production time30-40. More than % is the ideal equipment for fine grinding and deep processingof fly ash.

Fly ash ball mill structure

Fly ash ball mill structure, the main fromthe feeding part, the cylinder part and the discharge part of the working partand the bearing seat, the size of the gear, reducer, coupling and othertransmission parts, motors, electronic control parts and other components.

1. Stake plate, with hole guard plate:casting material manganese chromium alloy; quilting 5mm;

2. Screen frame: special for fly ashgrinding, made of imported wear-resistant steel plate;

3. Sieve plate: Stamping material δ3mmstainless steel; sieve seam 1.2-1.5mm;

4. Standard parts: (tube and sieve frame,bolts, nuts) depending on the mill specifications.