- +8618937185591

- +8618937185591

- ec19@zkcorp.com

- +8618937185591

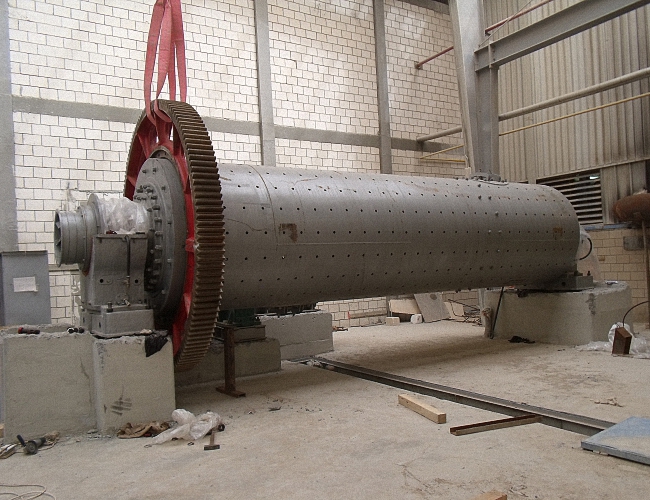

Wet ball mill gear installation as follows:

Wet ball mill gear installation

1. Cleaning the wet ball mill gear

2. Check the gear: smooth tooth surface, nocracks, burrs, shrinkage, loose; clean the combination of surface, bolt hole:no rust formation of the flange, aperture, hole number, pitch in line with thedrawings; Loop, measuring the ovalness of the ring gear, should be within theallowable range.

3. Before the installation of large gearmeasuring cylinder end cap connecting surface of the radial axis of thewhistling, record the location and direction of the largest whimsical point forthe installation of large gears to find reference to provide reference data.

4. The gear installation order is: thecylinder mounted gear ring position to the upper part, check the alignment markto determine the ring gear lifting direction and tie rope point, lifting gearhalf ring gear. After the first half-ring gear is installed, turn it to thelower part and install another half-ring gear. Into the bearings before turninginto the appropriate amount of lubricant, due to the rotation is too heavy, becareful.

5. The first gear when installing standardbolts, and then install the connecting bolts, connecting bolts should not betoo tight, until the two half ring gear are installed and then tighten thebolts.

Wet ball mill reducer and motorinstallation

Gear reducer and motor will be installed tofind the positive pinion as a reference to find, find out later, the anchorbolts and the basic framework for grouting. When grouted concrete strength todesign strength after the fastening bolts can be.

Wet ball mill pinion installation

The wet ball mill pinion and its fixedbearing hoist on the basis of the center line, with a tilting horn to adjustthe level and level of the shaft. Measure the flank and tip clearance,measuring 45 ° once per revolution. Measure once according to the flankclearance and adjust the pinion fixed bearings to meet the requirements for thetip and flank clearances of large and small gears, then check the gear contactby color printing. Generally not less than 50% along the tooth height, not lessthan 60% along the tooth width, and may not be biased to one side. Find rightafter the grouting of the anchor bolt hole, when the grouting strength of 70%of the design strength of the reconciliation to find work to find correct afterthe anchor bolts. Spot welds and grout the floor. The above is the wet ballmill pinion installation method - This article from ZK CORP ball mill column.