- +8618937185591

- +8618937185591

- ec19@zkcorp.com

- +8618937185591

【Capacity】:

10000-50000(t/a)【Main Materials】:

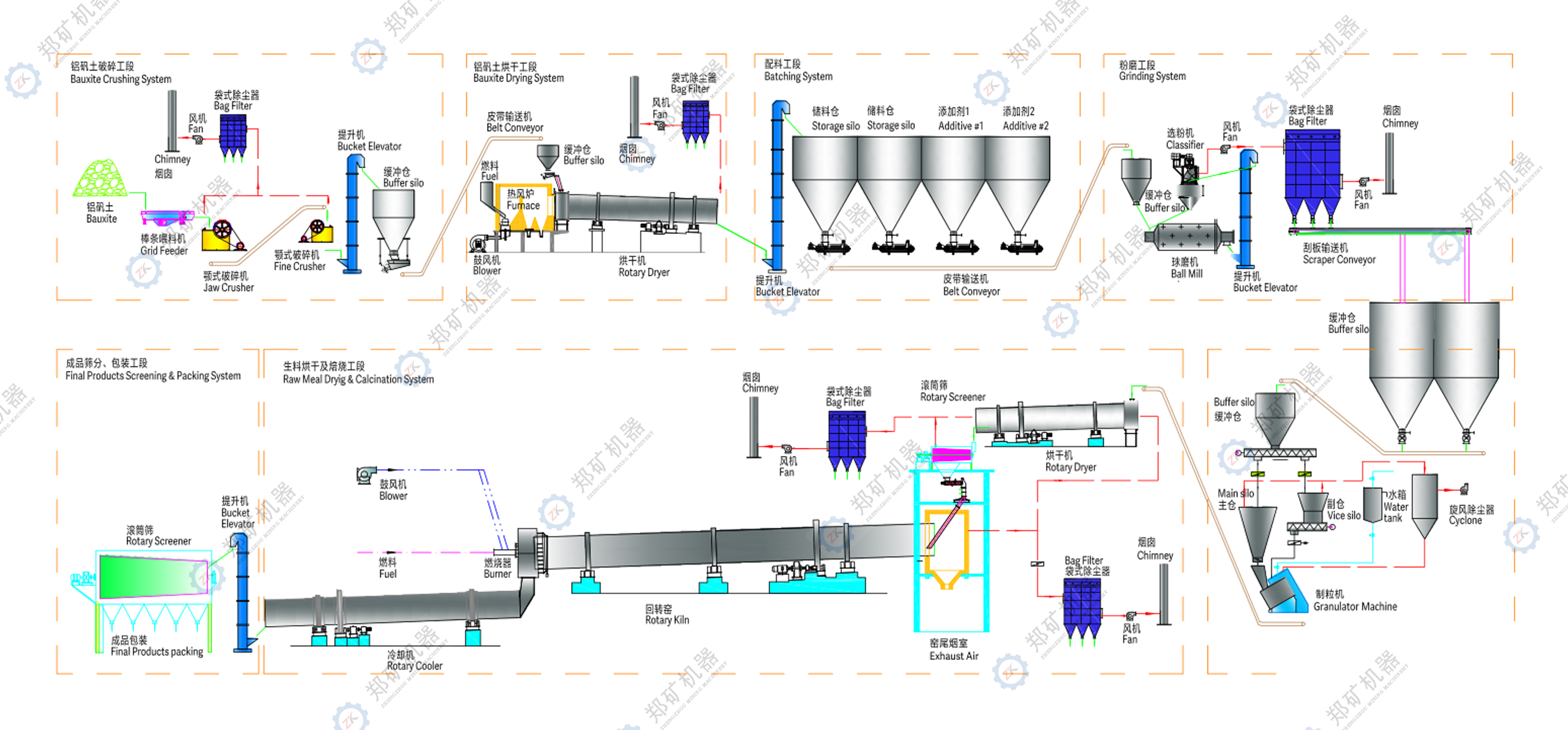

Bauxite,manganese powder and additives【Main Equipment】:

Dryer, powder separator, granulator, rotary kiln, cooler, rotary screen

Ceramic proppant, known as petroleum fracturing proppant, is one new type of material made from bauxite, manganese powder and additives by the process of crushing, drying, batching, pelletizing, calcining, cooling and sieving. Ceramsite proppant has the advantage of high strength, compression and abrasion resistance, good roundness, shock resistanceand good permeability resistance.

1. Advanced Pelletizing System

The ZKZL granulator developed by our company is special equipment for pelletizing in the ceramic proppant production process, which has the advantages of high production efficiency, full automation control, and no dust pollution.

2. Complete Set of Granulation Experimental System

We owns a complete set of granulation experimental production line, which can conduct experiments on customers' incoming materials, find out the best granulation technology for the materials, and give guidance for actual production.

3. Environmental Protection

Two phases of dust collection including cyclone filter and bag filter, will control the dust emission below the limitation of the national standard.

| Indicator | Unit | Quantities | |||

| Capacity | t/a | 10000 | 20000 | 30000 | 50000 |

| Low Density/High Strength Proportion | % | 80 | 80 | 80 | 80 |

| Raw Material | |||||

| Bauxite | t/a | 10400 | 20800 | 31200 | 52000 |

| Manganese powder | t/a | 200 | 400 | 600 | 1000 |

| Additives | t/a | 1000 | 2000 | 3000 | 5000 |

| Power consumption | |||||

| Fresh Water | t/a | 3000 | 6000 | 9000 | 15000 |

| Electricity | kWh/a | 2800000 | 5600000 | 8400000 | 14000000 |

| Gas | Nm3/a | 1800000 | 3600000 | 5400000 | 9000000 |

| General map transport | |||||

| Land Area | m2 | 30000 | 45000 | 61000 | 75000 |

| Staff | No. | 50 | 80 | 110 | 145 |

| Economic Indicators | |||||

| Investment | Million (CNY) | 9.6 | 15 | 18 | 27 |

| Profit Rate | % | 84 | 84 | 84 | 84 |

| Payback Period(After Tax) | Year | 1.53 | 1.53 | 1.53 | 1.53 |