- +8618937185591

- +8618937185591

- ec19@zkcorp.com

- +8618937185591

【Capacity】:

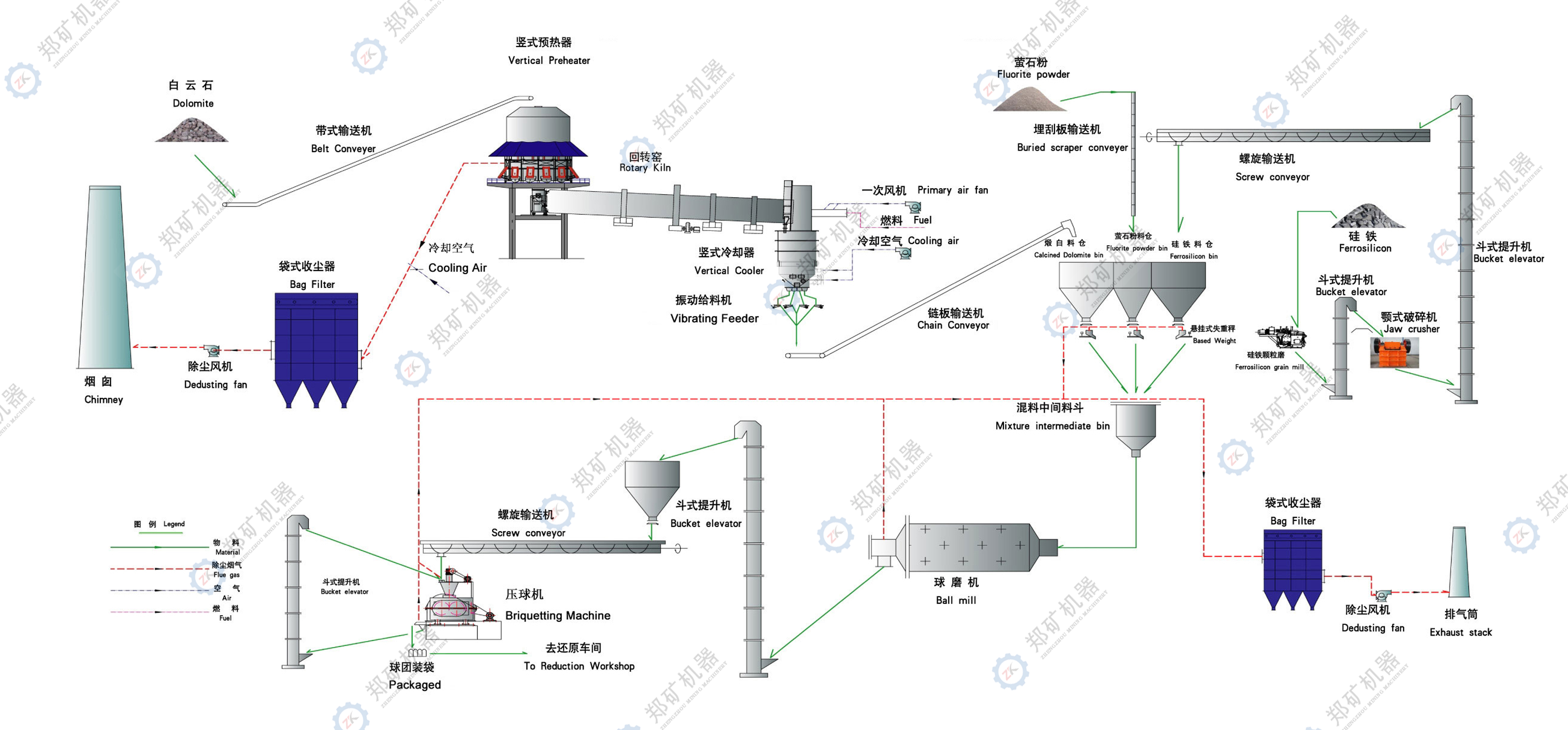

6000-50,000 t/a【Main Materials】:

Dolomite,Ferrosilicon,Flurite Powder【Main Equipment】:

Vertical preheater, ball mill, rotary kiln

We are leading manufacturer of complete equipment for magnesium production line, and over 90% market share. We have done many successful projects in both China and overseas countries. POSCO is world class iron and steel supplier in Korea. Their magnesium alloy production lines are supplied by us.

Henan Zhengzhou Mining Machinery Co., Ltd began to manufacture equipments for Mg smelting industry from 1988, and focused on the technology upgrading and utilization. During 2003-2005, the company invented Vertical pre-heater for the calcination of dolomite. This kind of new pre-heater saves fuel by 40% and increases the output by 30%. The exhaust gas is recycled and dust emission can be controlled under 50mg/m3. This kind of new pre-heater takes up more than 85% in the market share. The company has got the patent of energy-saving rotary kiln, vertical pre-heater and vertical cooler.

1. Our company's magnesium production lines at home and abroad in the lead industry, we have signed an annual output of 15000 tons of magnesium ingot project with the world iron and steel giant Korean Pohang iron POSCO company.

2. The company equipment use the latest technology, the operation process is simple, and the company also provide hands-on training.

3. We produce products with high quality, durable, welcomed by the majority of users.

4. Application,The company can according to the customer demand design various types of production equipment, the products can operations in all sorts of conditions.

5. Our magnesium production line equipment has high product quality, simple production process and other advantages, welcome customers to order.

| Model (m) | Basic Parameters(t/h) | Reducer | Electric Motor | Qty of Support (No.) | Equipment Weight(t) | |||

|---|---|---|---|---|---|---|---|---|

| Reloving Speed (r/min) | Slope(%) | Capacity (t/h) | Model | Model | Power(KW) | |||

| φ1.6×32m | 0.58-2.85 | 4 | 2 | ZQ75-50 | YCT250-4A | 18.5 | 3 | 46.8 |

| φ1.6/1.9×36m | 0.53-1.59 | 4 | 2.5-3 | ZQ110-7 | YCTZ50-4B | 22 | 3 | 57 |

| φ1.9×39m | 0.53-1.59 | 4 | 3-3.4 | ZQ125-7 | YCT315-4A | 37 | 3 | 71.79 |

| φ2.2×45m | 0.214-1.64 | 3.5 | 4-5 | Main ZS125-5 | YCT315-4B | 45 | 3 | 142.6 |

| Auxiliary:ZQ40-40 | Y112M-4 | 4 | ||||||

| φ2.5×50m | 0.62-1.5 | 3.5 | 5-6 | Main:ZS165-5 | YCT355-4A | 55 | 3 | 180 |

| Auxiliary:ZS50-1 | Y160M-6 | 7.5 | ||||||

| φ2.5×55m | 0.62-1.5 | 3.5 | 5-6 | Main: ZS165-5 | YCT355-4A | 55 | 3 | 185 |

| Auxiliary:ZS50-1 | Y160M-6 | 7.5 | ||||||

| φ2.8×55m | 0.62-1.5 | 3.5 | 6-7 | Main: ZS165-5 | YCT355-4B | 75 | 3 | 215.6 |

| Auxiliary:ZS50-1 | Y160L-6 | 11 | ||||||

| φ3.0×60m | 0.5-1.5 | 3.5 | 7-9 | Main:ZS165-3 | ZSN-280-11B | 125 | 4 | 310.9 |

| Auxiliary:ZS50-1 | Y160L-6 | 11 | ||||||

| φ3.2×64m | 0.4-1.5 | 3.5 | 8-10 | Main: ZS130-16 | ZSN-280-11B | 190 | 4 | 337.8 |

| Auxiliary:Zl50-1 | Y180L-4 | 22 | ||||||

| φ3.5×70m | 0.4-1.5 | 3.5 | 12-14 | Main: ZSY500-40 | ZSN-315-082 | 280 | 4 | 394.6 |

| Auxiliary:Zl50-14 | Y180L-4 | 22 | ||||||

| φ4.0×80m | 0.4-1.5 | 3.5 | 16-20 | Main: ZLY630-35.5 | ZSN-315-12 | 355 | 4 | 564.8 |

| Auxiliary: ZSY280-35.5 | Y200L-4 | 30 | ||||||