- +8618937185591

- +8618937185591

- ec19@zkcorp.com

- +8618937185591

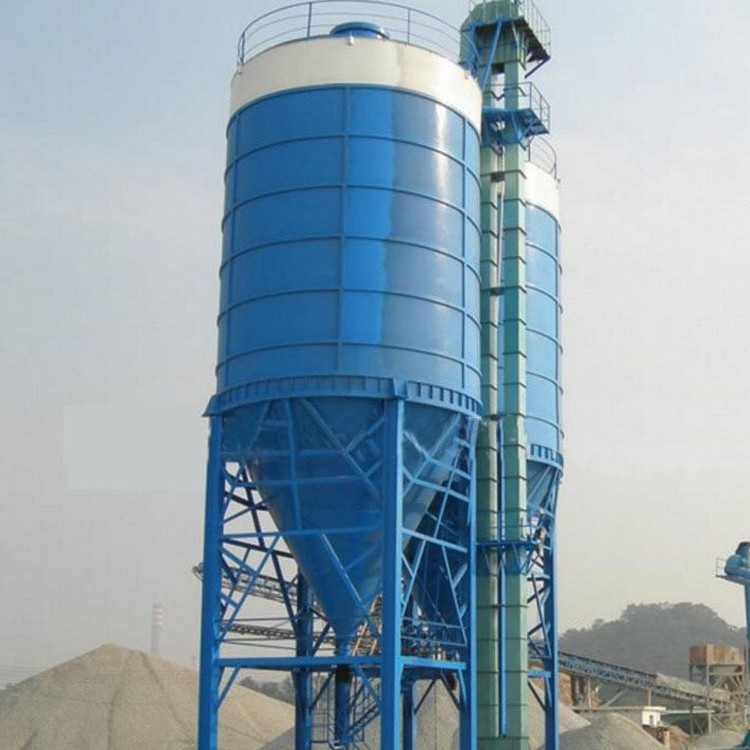

I. Brief introduction of TDG dual-channel steel wire tape elevator equipment

TDG double-channel steel wire belt elevator is a commonly used equipment for vertical lifting and conveying materials, which has the characteristics of large conveying capacity, high lifting height, good sealing performance, high strength, stable operation, low noise, small occupied area, energy saving and environmental protection, convenient maintenance, etc. It adopts inflow type, cutting type mixed loading, centrifugal-gravity type unloading, which can quickly lift the materials from the lower feeding port to the upper discharging port; Due to the particularity, it is not easy to scatter materials during transportation, and it is not easy to pile up materials at the lower part. Compared with other tape hoists, TDG double-Channel steel wire hoists are the best choice for users with limited working space and high requirements on the delivery volume. It is often used for vertical delivery of powder, granular and small block materials.

TDG double-Channel steel wire tape elevator is mainly composed of upper section, driving device, operating platform, middle chassis, bucket device and lower section, etc.

1. TDG double-Channel steel wire belt elevator has the advantages of large conveying capacity and high lifting height;

2. Reasonable bucket type and large capacity;

3. The adhesive tape adopts wire rope braided core adhesive tape, which has good toughness and high strength;

4. The head, tail and middle chassis of TDG double-Channel steel wire tape elevator are all sealed, and the materials and dust are not exposed, which will not cause environmental pollution;

5. Vertical axis reducer and hydraulic coupler are adopted in the transmission device, and counterstop device is equipped, which makes the structure of the transmission device compact and realizes flexible transmission. Not only can the operation be stable, but also the motor reducer and traction parts can be protected, and the materials can be kept stable when the machine is stopped, thus improving the service life of the main parts;

6. The lower part adopts a heavy hammer tensioning device to realize automatic tensioning. After one installation adjustment, constant tension can be maintained to avoid tape slipping, thus ensuring the normal operation of the equipment;

7. The central chassis adopts integral bending, which improves the strength and rigidity of the chassis as a whole. The chassis is a unique dual channel, and the inlet and outlet channels are independent boxes. The Middle chassis: the standard section is 2m; The non-standard section is between 0.5 m and 2m, which is generally installed at the middle chassis of the first or second section of the upper section; The overhaul section is one section for installation and overhaul of traction parts; Anti-yaw section, usually a group of middle chassis is placed on one side; Connection frame, usually one is placed in the middle case every five sections; The connecting plate is usually placed in the middle case every two sections.

8. The height of the elevator can be adjusted arbitrarily according to the working conditions, and the process layout is flexible and convenient;