- +8618937185591

- +8618937185591

- ec19@zkcorp.com

- +8618937185591

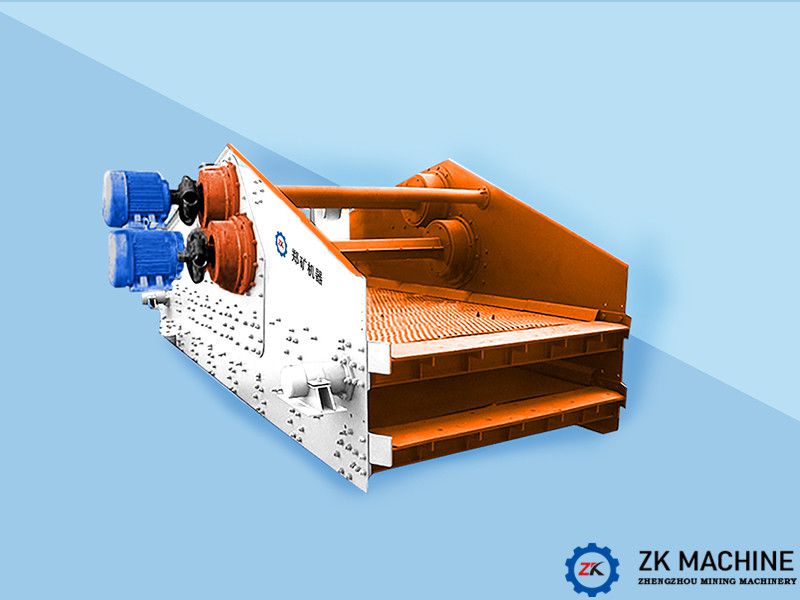

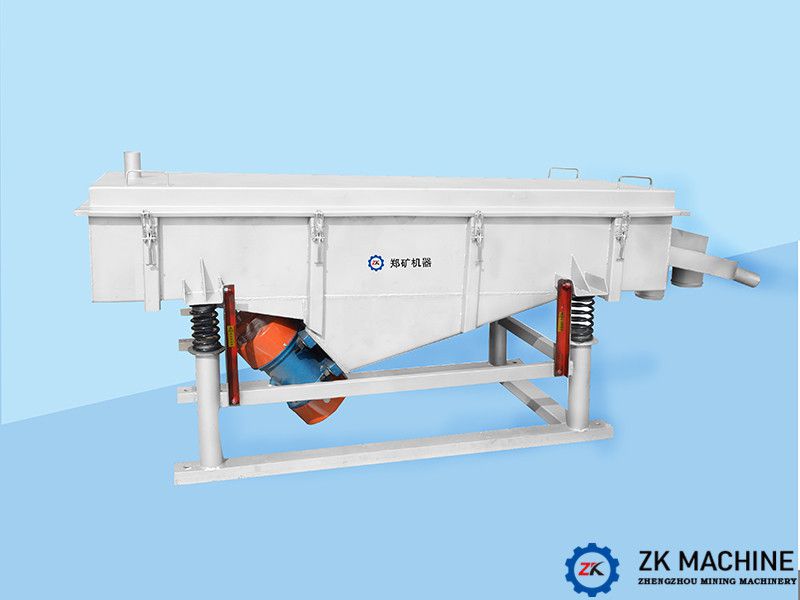

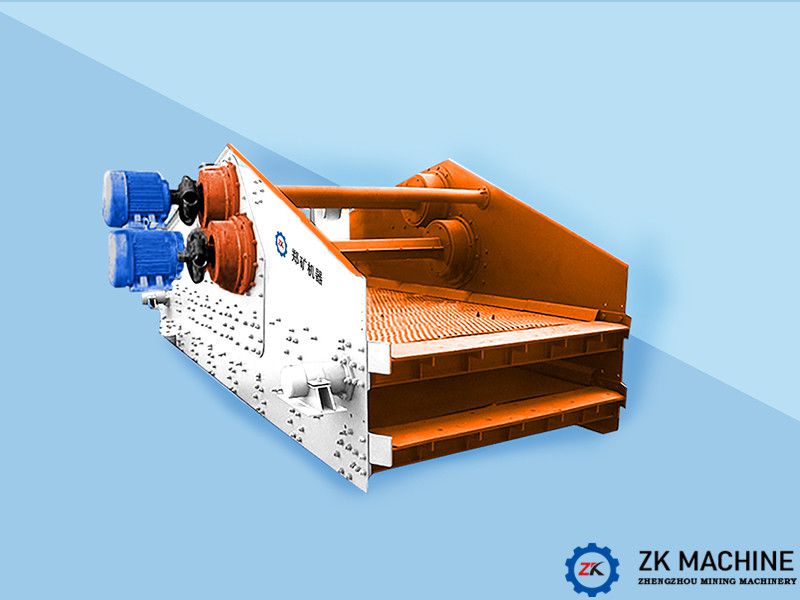

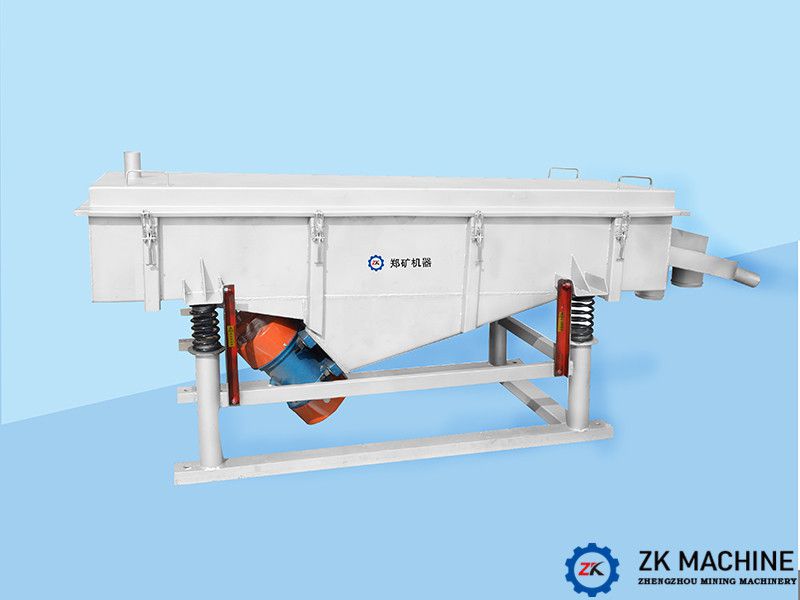

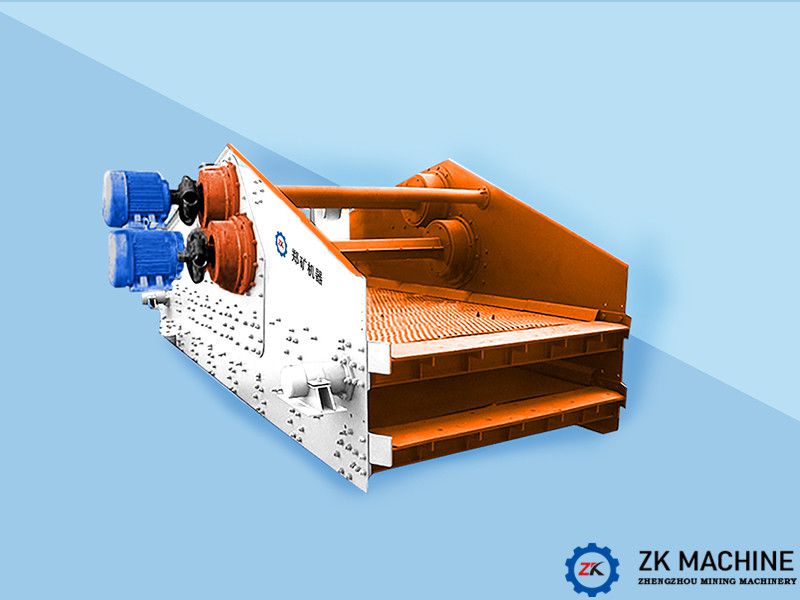

ZK Linear vibrating screen has a unique effect on powdery, granular materials selection and classification. It uses a vibrating motor to throw materials in an upward and forward linear motion. These models typically operate with twin-vibrating motors that function in a synchronized fashion and move the centrifugal force parallel to the motor access. Centrifugal and gravity force help throw the material in the direction it moves, which effectively reduces its size and grades it.

Linear vibrating screens are available in single or double deck types with sizes up to four meters wide and nine meters long. They’re known for being rugged, stable and simple to maintain. Typical applications include primary and secondary classification, sizing, de-sliming, washing, dewatering and hot-material screening, among others.

Advanced design, ingenious and easy to assemble, easy operation, high efficiency of processing capacity.

Unique screen structure design, convenient and fast change screen (only 3 to 5 minutes), in addition, this design allows the use of a variety of screen (nylon, special dragon, PP nets).

High degree of standardization, stable and reliable operation, low noise.

Large processing capacity, reasonable technical parameters.

| Model | Screen Area (㎡) | Screen Inclination Angle(°) | Feed Particle Size (mm) | Motor Power (kW) | Capacity (t/h) | Weight (t) |

| ZK1022 | 2.25 | -5~5 | <250 | 3x2 | 4.5-90 | 2.2 |

| ZK1230 | 3.6 | -5~5 | <250 | 4x2 | 7.2-144 | 2.6 |

| ZK1237 | 4.5 | -5~5 | <250 | 5.5x2 | 9-180 | 3.1 |

| ZK1437 | 5.25 | -5~5 | <250 | 5.5x2 | 12-250 | 3.2 |

| ZK1445 | 6.3 | -5~5 | <250 | 7.5x2 | 12.6-252 | 4.1 |

| ZK1637 | 6 | -5~5 | <250 | 5.5x2 | 12-240 | 3.5 |

| ZK1645 | 7.32 | -5~5 | <250 | 11x2 | 95-280 | 4.5 |

| ZK1837 | 6.75 | -5~5 | <250 | 11x2 | 90-270 | 5 |

| ZK1845 | 8.1 | -5~5 | <250 | 11x2 | 16.2-234 | 5.5 |

| ZK1852 | 9.45 | -5~5 | <250 | 11x2 | 18.9-378 | 5.9 |

| ZK2045 | 9 | -5~5 | <250 | 11x2 | 16.2-324 | 6 |

| ZK2052 | 10.5 | -5~5 | <250 | 11x2 | 21-420 | 6.4 |

| ZK2060 | 12 | -5~5 | <250 | 15x2 | 24-480 | 7.6 |

| ZK2445 | 10.8 | -5~5 | <250 | 15x2 | 21.6-432 | 7.4 |

| ZK2452 | 12.6 | -5~5 | <250 | 15x2 | 25.2-504 | 8.2 |

| ZK2460 | 14.4 | -5~5 | <250 | 15x2 | 28.8-576 | 9.2 |

| ZK3045 | 13.5 | -10 | <250 | 15x2 | 27-540 | 10 |

| ZK3052 | 15.75 | -5~5 | <250 | 22x2 | 31.4-628 | 10 |

| ZK3060 | 18 | -5~5 | <250 | 22x2 | 17.5-525 | 11 |

| ZK3645 | 18 | -5~5 | <250 | 22x2 | 37.8-756 | 12.2 |