- +8618937185591

- +8618937185591

- ec19@zkcorp.com

- +8618937185591

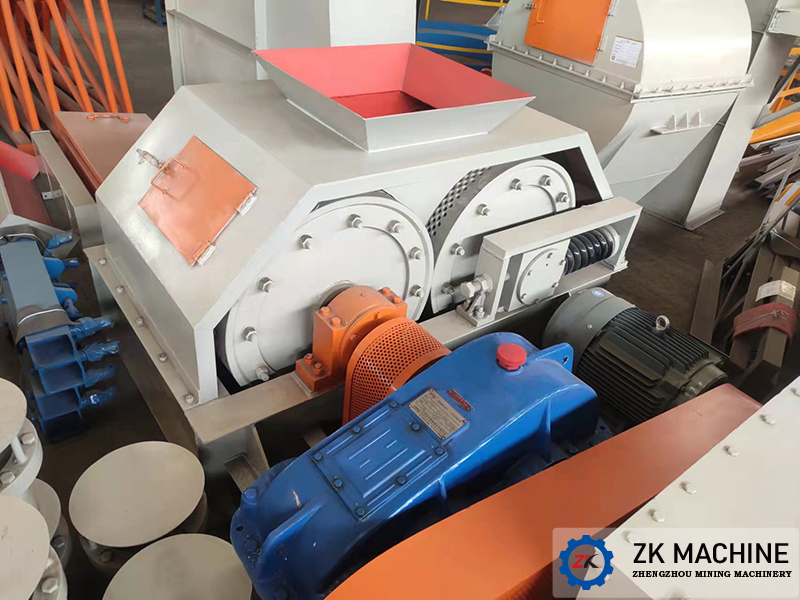

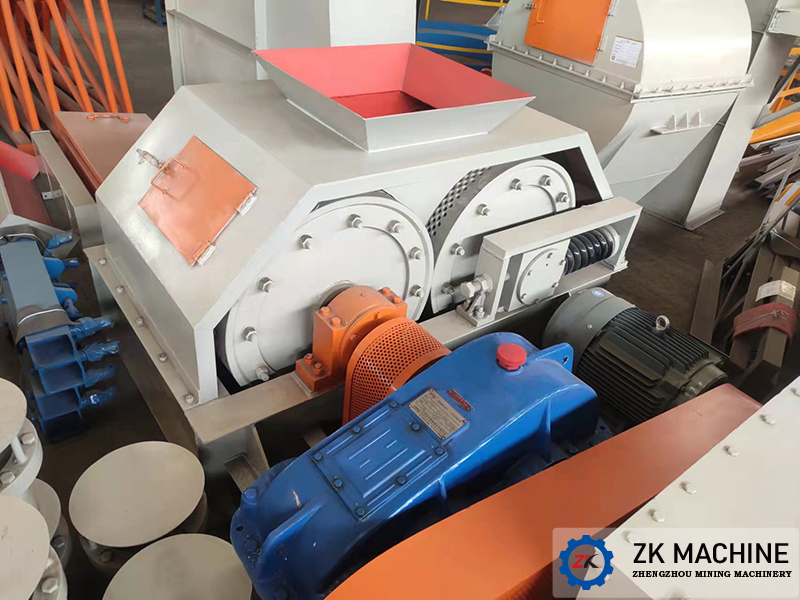

The double roll granulator is a molding equipment capable of forming a powder or small granular material into a specific shape, and is mainly composed of a movable roll device, a fixed roller device, a roller support bearing, an adjusting device, and a driving device. It is characterized by smoothness, low noise, less dust, reliable performance and convenient maintenance. It can be widely used in construction, mining and metallurgy, environmental protection and other industries.

The granulator has the characteristics of uniform granulation, high yield, large output, compact structure, reasonable layout, small floor space and high automation.

With advanced technology and stable quality, this type of roller granulator developed for the calcination characteristics of ceramsite has won unanimous praise from customers.

High production efficiency, high ball formation rate.

The discharging is uniform. The ceramsite produced by the roller granulators is uniform in size, which can meet the requirements of the ceramsite rotary kiln for the size and shape of the ball.

The overall operation of the equipment is stable and the noise is low. At the same time, it adopts the sealed cover to receive the material, and the site is clean and tidy, reducing the labor intensity of the workers.

| Model | Roller diameter(mm) | Roller length(mm) | Extrusion bore diameter(mm) | Roller rotating speed(r/min) | Capacity(t/h) | Installed power(kW) |

|---|---|---|---|---|---|---|

| GL450×400 | 450 | 400 | 8-16 | 58 | 2-5 | 11 |

| GL610×700 | 610 | 700 | 8-16 | 40 | 5-8 | 18.5 |

| GL700×600 | 700 | 600 | 8-16 | 36 | 5-8 | 18.5 |

| GL800×700 | 800 | 700 | 8-16 | 30 | 8-12 | 18.5 |

| GL1000×900 | 1000 | 900 | 8-16 | 26.4 | 10-15 | 30 |