- +8618937185591

- +8618937185591

- ec19@zkcorp.com

- +8618937185591

1. Project overview:

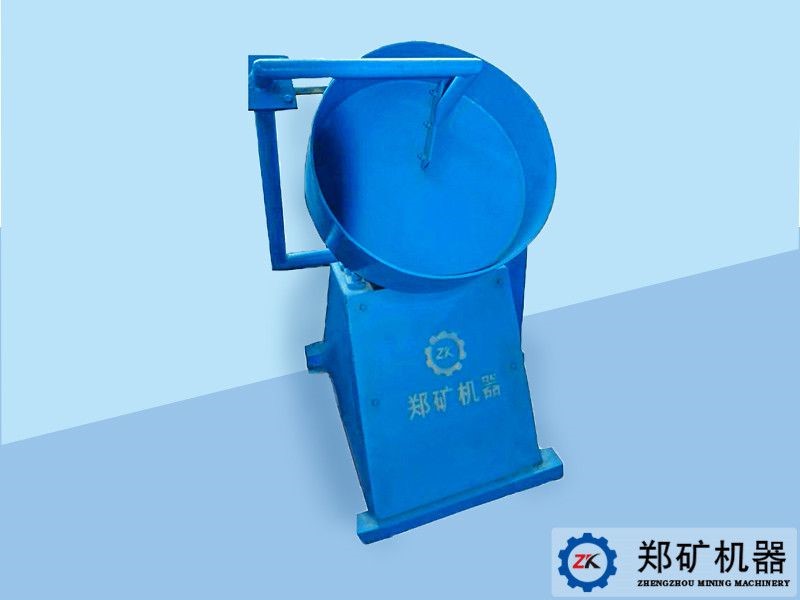

The owner of this project requires the disc granulator to make balls, material clay, and relevant materials have been proportioned to make 3-5mm products, which are used for laboratory experiments and have no relevant capacity requirements.

2. Solution:

The Raw Meal powder is made into a ball core with uniform grain size, and then sent into the ball plate. After entering the ball plate, the ball core is affected by centrifugal force, friction force and gravity, and moves along parabola. In the process of continuous rolling, the water in the ball is continuously squeezed out of the surface. Due to the cohesiveness and plasticity of materials, the ball core is mutually bonded with the raw meal powder during the process of movement and gradually grows up. Due to the cohesiveness of the material and the natural volatilization of the surface liquid film, the material ball has a certain strength. When the parameters such as the inclination angle, the height of the edge of the disc, the rotation speed and moisture content of the spherical disc are fixed, the material balls with different particle sizes leave the edge of the disc and roll downward according to different separation angles due to different gravity, then discharge them out of the edge of the disc along with the rotation of the inclined disc body, and finally make the products with relevant particle sizes according to the requirements.